penny@vodarengineering.com

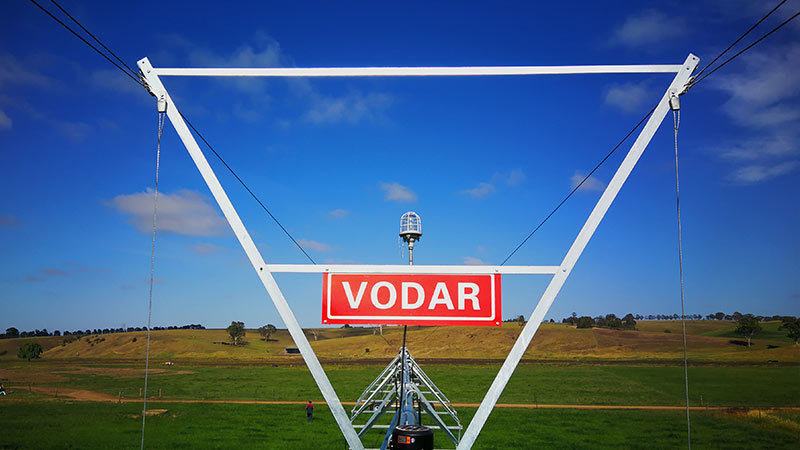

VODAR ADVANTAGE

Vodar Sprinkler Relative Advantage

Technical process

American Technology Process The lower chord of the span is longer than the upper chord, the center of gravity is low, and the ability to resist reverse voltage and climb slopes is strong. B, truss angle width to improve wind resistance C, cross-body ball hole type flexible connection, can be flexible movement in complex terrain without stress

Reliable quality

The core components are imported, the main components are produced by themselves, and the quality can be traced back. A, electric control box using the United States Eagle percentage table, Schneider and Siemens and other core components. B. The walking system adopts VODAR professional customized high-performance motors and reducers, as well as special tires. C, spraying system using the United States Nielsen D3000 and R3000 series or Italy Komet KPT series World-famous sprinkler for sprinkler irrigation machine D, the cable adopts 11 core with armor special copper cable

Scale

With an annual output of 5000 sets of sprinkler irrigation machines, it is produced by domestic and foreign counterparts all the year round. As of 2017, Vodar has sold more than 12000 sets of sprinkler irrigation machines at home and abroad, with an irrigation area of over 6 million mu, which is currently China's Sprinkler market production and sales of the largest production enterprises. In 2017, Vodar was selected as the sixth leading manufacturer of sprinkler irrigation machines in the world.

Quality service

Vodar has more than 50 experienced technical engineers, providing users with lifelong After-sales service.

SERVICE PROCESS

Engineered in China, Trusted Worldwide

Topographic survey

01

Design Planning

02

Quotation

03

Signing a contract

04

Production arrangements

05

Packing and shipping

06

Installation training

07

After-sales service

08